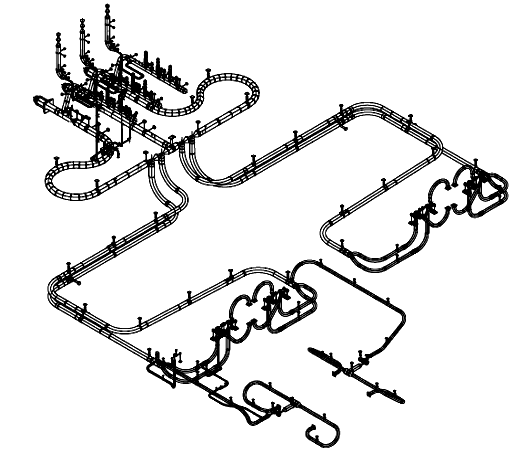

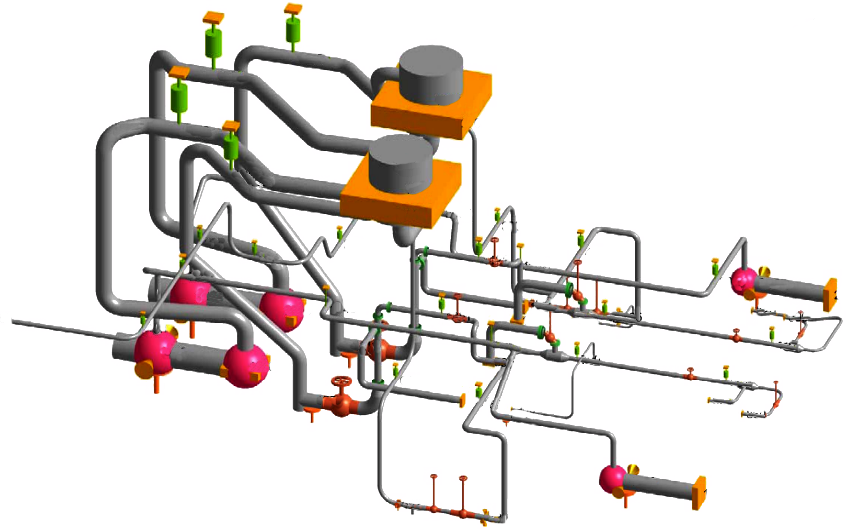

Piping Design & Engineering

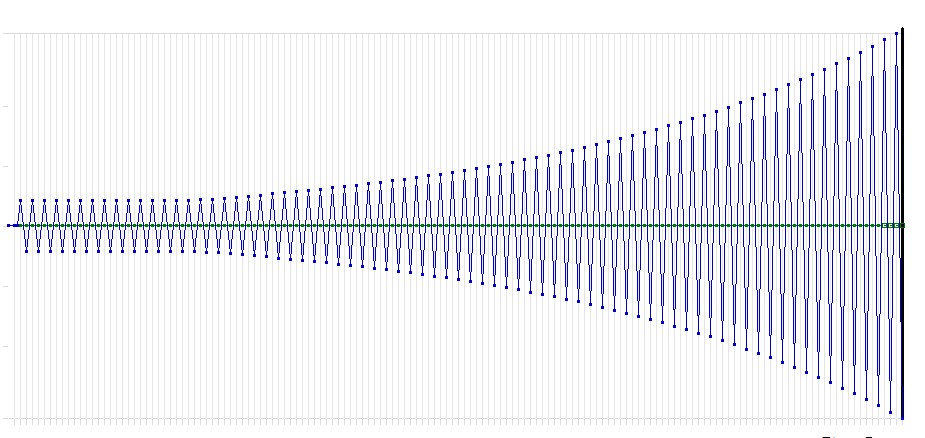

Pipe Stress Analysis

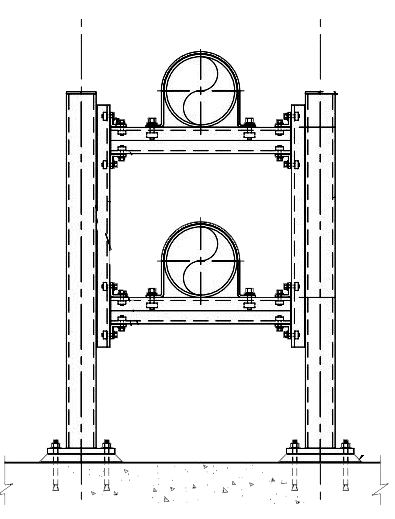

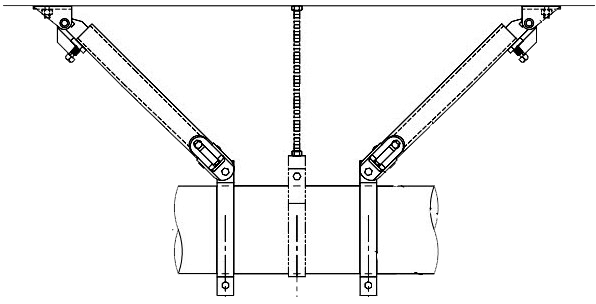

Pipe Support Design

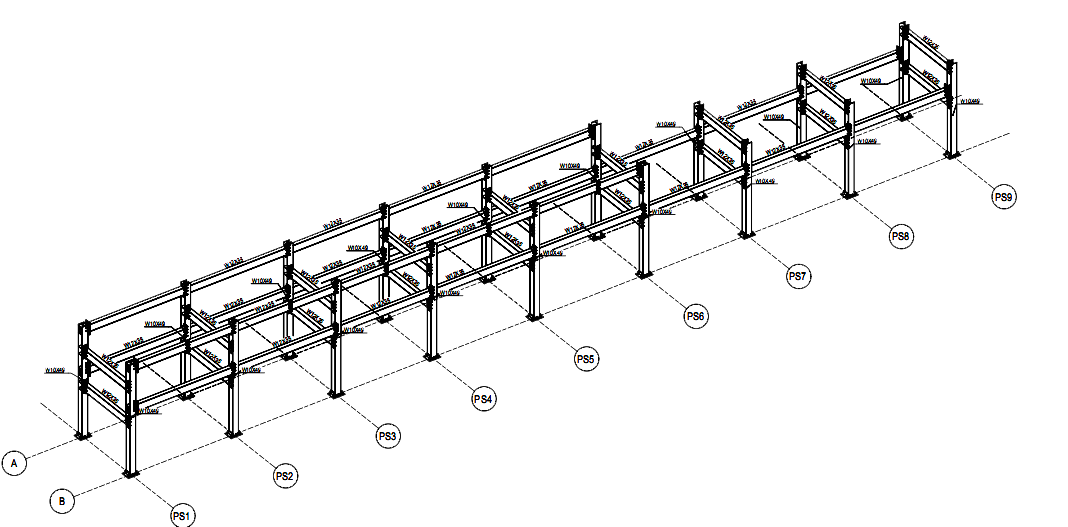

Pipe Rack & Skid Design

Foundation Design

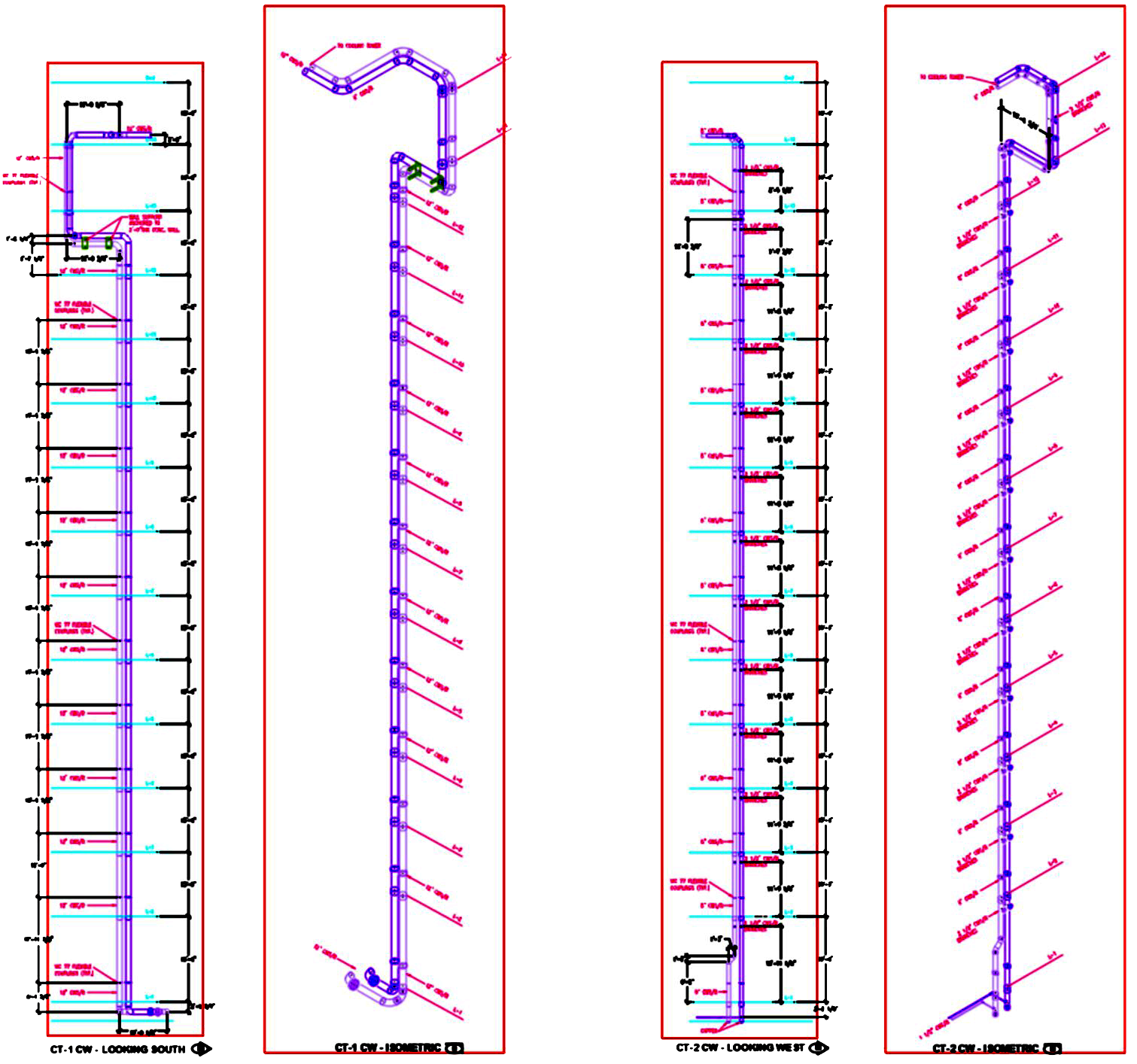

Pipe Risers Design

Seismic Layout Design

Failure Analysis

CAE Piping regularly teams up with general contractors, architects, and projects owners in the design and engineering of the piping systems (process and power piping), pipe risers and underground pipelines, and mechanical components. We are specialized in performing Pipe Stress Analysis, Failure Analyses, and Seismic Analysis on the industrial and commercial pipelines and mechanical components based on ASME, AISC, and ASCE/IBC, and other applicable standards, utilizing the Finite Element Method.

About Us

CAE Piping, Inc. is an engineering firm made up of experienced licensed professional engineers with over 20 years of experience and registered in California. We provide a full engineering package for the design of non-structural components such as storage tanks, boilers, cooling towers, generators, piping systems, electrical conduits, and cable trays.

We perform various types of engineering analyses on the piping systems and mechanical components of the process and power plants as well as other industrial and commercial facilities based on ASME, AISC, ASCE and other applicable codes. We believe that, quality of our works, reliability and dedication to our customers' needs is what makes us successful.

We use the latest CAE technology to analyze and develop your pipelines, boilers, cooling towers, etc., based on the applicable codes and standards. You will be able to see the result of the analyses performed on a 3D model and summarized in a professional technical report. . This will provide an easy to use platform for collaboration to enhance our joint ability to identify critical points of the design. This process can also be used to streamline the Critical Design Review (CDR), saving valuable business development resources and maximize the ROI of your company. We believe that quality of our works, reliability and dedication to our customer needs is what makes us successful

We perform various types of engineering analyses on the piping systems and mechanical components of the process and power plants as well as other industrial and commercial facilities based on ASME, AISC, ASCE and other applicable codes. We believe that, quality of our works, reliability and dedication to our customers' needs is what makes us successful.

We use the latest CAE technology to analyze and develop your pipelines, boilers, cooling towers, etc., based on the applicable codes and standards. You will be able to see the result of the analyses performed on a 3D model and summarized in a professional technical report. . This will provide an easy to use platform for collaboration to enhance our joint ability to identify critical points of the design. This process can also be used to streamline the Critical Design Review (CDR), saving valuable business development resources and maximize the ROI of your company. We believe that quality of our works, reliability and dedication to our customer needs is what makes us successful

MISSION STATEMENT

The Mission of CAE Piping is to provide reliable and cost effective solutions in Piping Design and Engineering, Seismic Design and Engineering and Mechanical Engineering to the industrial and commercial sectors. We are committed to Safety, Quality, Experience, Integrity and Teamwork.

VISION STATEMENT

The Vision of CAE Piping is to be the leading engineering firm in the field of piping engineering nationwide.